FOOD METAMORPHOSIS

Revolutionary recipes and designs

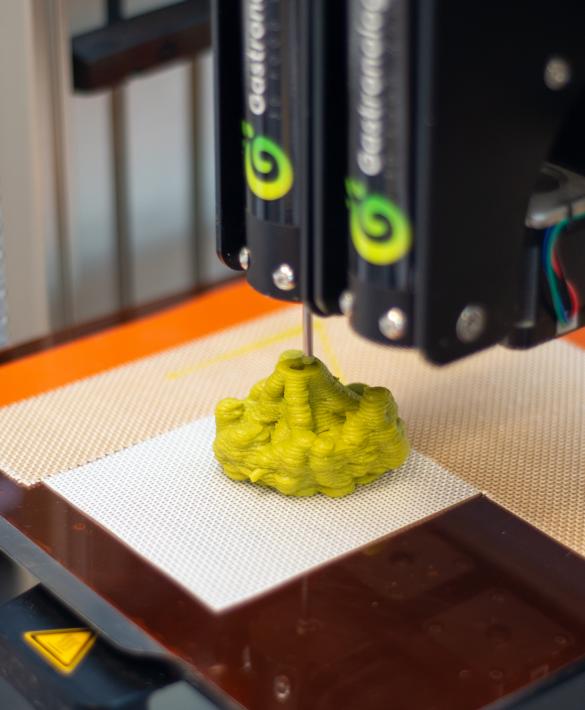

Gastronology creates delicious 3D printed food recipes with a lot of flavour and a functional or fun shape. We develop appealing, recognizable food shapes that look identical to normal solid food. The colour, shape and perception are the same, only the bite is different because it is soft instead of al dente. This makes it ideal for people with dysphagia. We also develop fun and experimental shapes which are deliberately looking different than ordinary food. This makes it irresistible to, for example, young children.